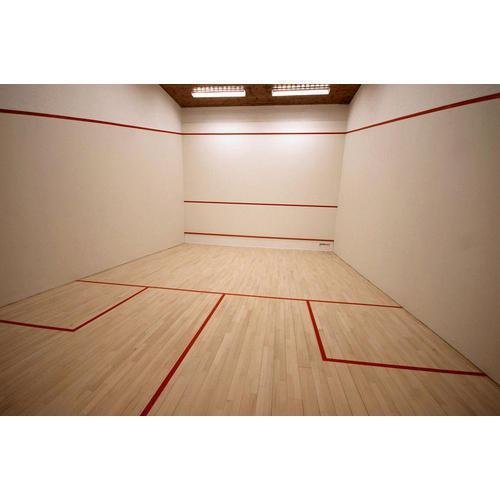

MULTI PURPOSE Wooden Sports COURT

Product Details:

- Color Brown

- Feature Non-Slip Anti-Aging Easy To Install Environmentally-Friendly Antibacterial Waterproof Anti-Slip

- Click to View more

MULTI PURPOSE Wooden Sports COURT Price And Quantity

- 1000 Square Feet Square Foot

MULTI PURPOSE Wooden Sports COURT Product Specifications

- Non-Slip Anti-Aging Easy To Install Environmentally-Friendly Antibacterial Waterproof Anti-Slip

- Brown

MULTI PURPOSE Wooden Sports COURT Trade Information

- Letter of Credit (L/C) Paypal Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- Yes

- Free samples are available

- All India

Product Description

Surface Board:- Made of Kiln Seasoned (moisture containt of approximately 14% at the time tiome of dispatch), Treated Wood finished with 21 mm thick, 57 to 83 mm wide and in random length in tongue and groove shape. The edges of the boards will have a finger lock groove and the bottom side with air pass groove and treated with special anti termite and water resistant lacquer.

The Under Frame:- Made of commercial quality pine wood runners of 70 mm x 45 mm, treated with antitermite solution and fixed on the bottom side with 10 mm thick air cushioned pads, stappled through the two wings at 350 mm x 350 mm

Installation:-IPS subfloor treated with a vapour barier to be placed on the leveled IPS sub-floor before

laying the under frame. The runners having air cushion pads to be placed on the vapour barier in perfect

level at 350 mm in 1 direction. The surface board to be screwed to the runner through the tongue only and

will lock the screwed tongue by the groove of adjoining board. Ends of the boards will be locked by

inserting the wooden fingers through the edge grooves and fixed with suitable adhesive. An expansion of 8 to 10 mm to be left open between the wooden flooring and the surrounding tiled area / walls

Finishing:- After laying the flooring, the floor boards will be levelled to a uniform surface and applied a thin coat of water based police on the the face

Additional Information:

-

Delivery Time:Within 2 Days After the Receipt Of Payment

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Wooden Sports Flooring' category

|

J P ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |